Digital Revolution

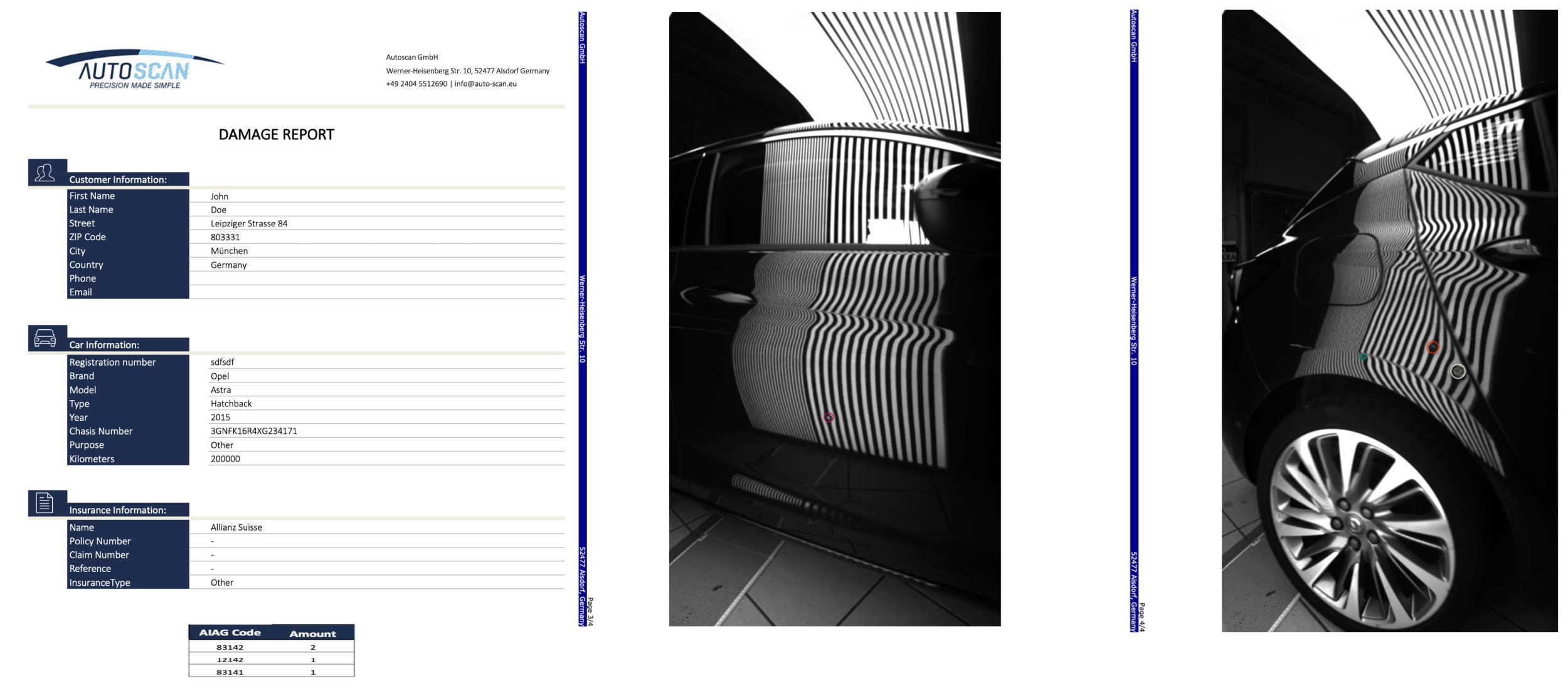

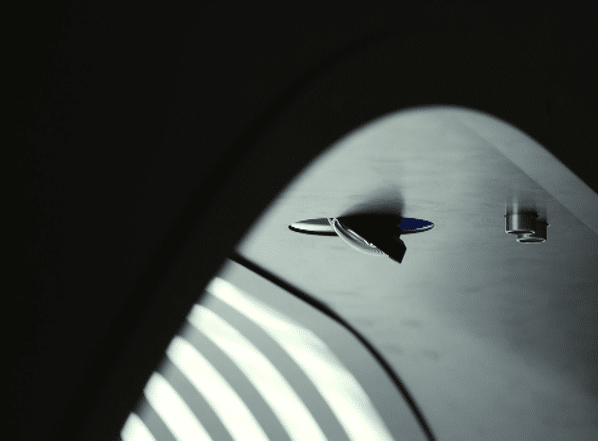

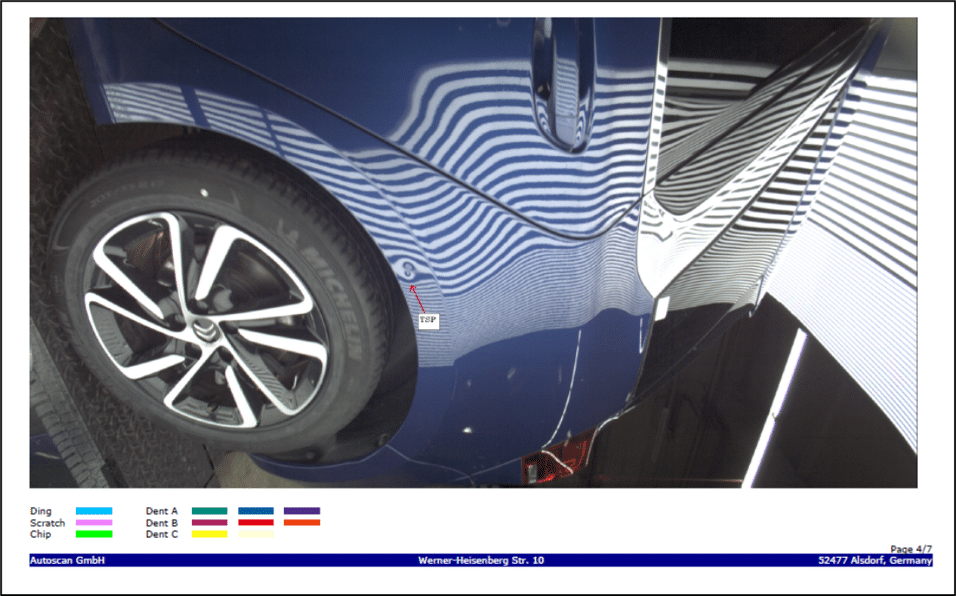

Five high-performance cameras record the car body in every detail, providing a clear and objective view of dents, not just like the eyes of a human expert, but actually better.

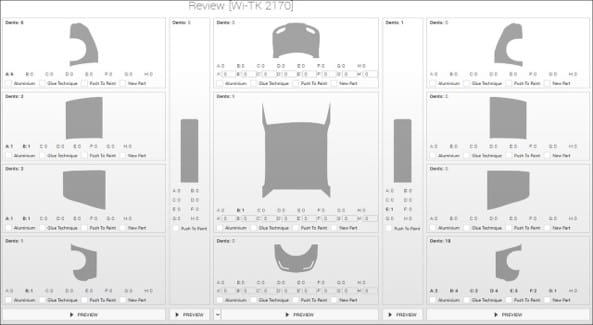

All dents are digitally recorded and transferred to a cloud repository for later consultation. They are also sized and counted to produce a detailed digital report, and an accurate and ojective evaluation of estimated repair cost.

This is a quantum leap from previous recording means: manual inspections, verbal descriptions or at best low-quality mobile phone pictures.

Applications & Further evolutions

Autoscan is a support tool for experts at work, recording and accurately estimating the damage. It can also be used to certify the repair, by recording the damage-free body after work. It is protected by a world-wide patent, and licensing in some markets is already ongoing.

Although Autoscan has been developed inside the KHS Group of companies with a focus on hail dents, it is capable of detecting and recording other surface damages such as scratches, broken paint, chipped glass, with additional evolutions such as tire check, paint color code analyzer and others already in the development pipeline.

Autoscan has also been adapted to perform estimation of massive hail damages (thousands of cars hit by a hailstorm), with the Scantainer, our latest trade-marked, patent-protected innovation. Fast deployment anywhere with a fully autonomous container, and ultra-fast hail damage scanning and estimation: up to hundreds of cars a day.

Advanced IT support systems

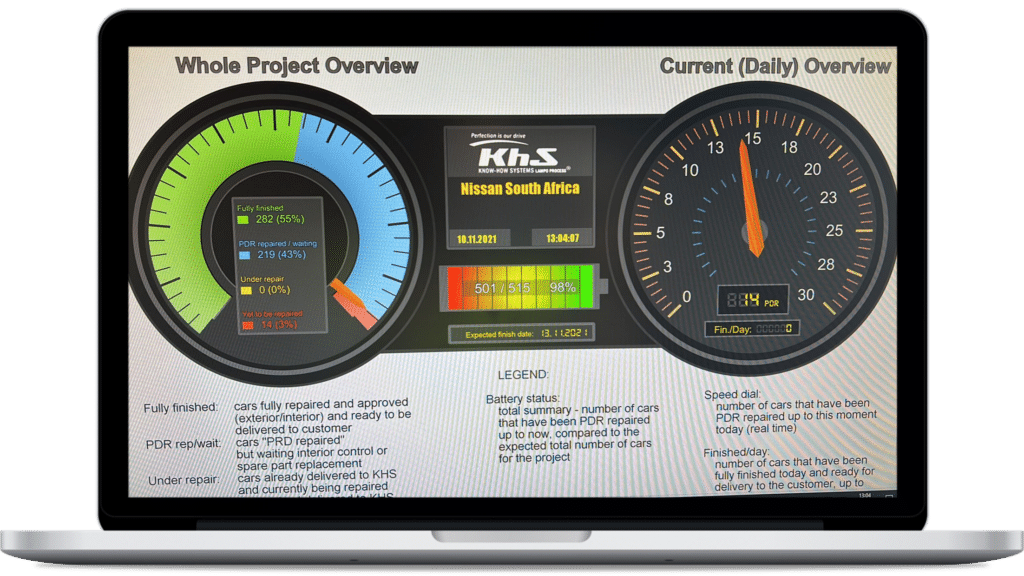

Since the industry did not have them, we developed our own advanced IT support systems, termed "CarLoS" (Car Logistics Services).

In particular, our CarLoS Commercial supports mass hail repair projects, by automating and digitizing every step and every aspect: from car entry (together with Autoscan), thru dismantling, technical repair work, remantling, quality checks, to car exit (checked with Autoscan). The system is deployable everywhere with a movable set-up based on a central processor and hand-held terminals that can work all around the compound. It provides our customers with a real-time status of all vehicles and all activities in the compound, and a detailed automated real-time customer reporting.